کلینیک فوق تخصصی دانش آموخته لوله کشی صنعتی ۸۳-۸۴ ( نفت و گاز ) - مایترکاری

سایتی نو و نخست برای ارائه راهنمای ساخت انواع شابلون پایپینگ به Fabricator ها و بالا بردن دانش ریاضی ایشان

کلینیک فوق تخصصی دانش آموخته لوله کشی صنعتی ۸۳-۸۴ ( نفت و گاز ) - مایترکاری

سایتی نو و نخست برای ارائه راهنمای ساخت انواع شابلون پایپینگ به Fabricator ها و بالا بردن دانش ریاضی ایشاندرباره من

نظرسنجی

روزانهها

همه- حد پذیرش تست مایعات نافذ Asme Viii Appendix 8

- افسانه شیان فان

- انهدام شبکه جاسوسی در یمن شکست غرب و اروپا در یمن

- طرح نعل اسبی سایت موشکی در سوریه آماده برای شلیک به اسرائیل

- قضیه تالس

- داروی اوسلتامیویر (تامی فلو) برای درمان و پیشگیری از آنفولانزا داروی آنفولانزا

- عزیز جون پرستو ... کنسرت کاروانسرا

- Y Ducting Connector تبدیل Y شکل گالوانیزه Air Ducting

- سایت

- تفسیر قانون پذیرش پزشکی بدون کنکور المپیک 2024

- طرح جدید پذیرش بدون کنکور پزشکی المپیکیها مدال بیار بدون کنکور رشته پزشکی بخون

- مسابقات جهانی آرایش

- جولان افاغنه در ایران از خرید تا اجاره ملک

- یا حسین میر حسین

- کیست تخمدان مراجعه به پزشک زنان قبل از وقوع یا مرحله کم خطر بودن

پیوندها

- برخورداستوانه و مخروط

- برنچ

- رفتارشما

- Jalali Calendar میلادی-شمسی

- Whats app دانلود

- Fabrication راهنمای ساخت

- Slope In Piping روش محاسبه شیب در پایپینگ

- شکستگی و پروتز گردن ران ( فمور )

- ساپورت دامی - زانوئی چند تکه - شلوارک

- مهسا امینی دستگیری بعلت بدحجابی ، از سکته او در پلیس امنیت در جریان بحث و وفات در بیمارستان کسری تهران دهه سوم شهریور ۱۴۰۱

- رحم اجاره ای اخاذی بین ۱۰۰ تا ۲۰۰ میلیون و ماهی ۳ میلیون در سال ۱۴۰۱ و نبود قانون

- مهسا امینی - اعتراضات اواخرشهریور ۱۴۰۱

- اعتراضات شهریور۱۴۰۱

- احکام 18+

- قانون Control Banding بازرسی محوطه کاری ، سرزمینی یا مرزهای دریایی

- The day of revenge is near

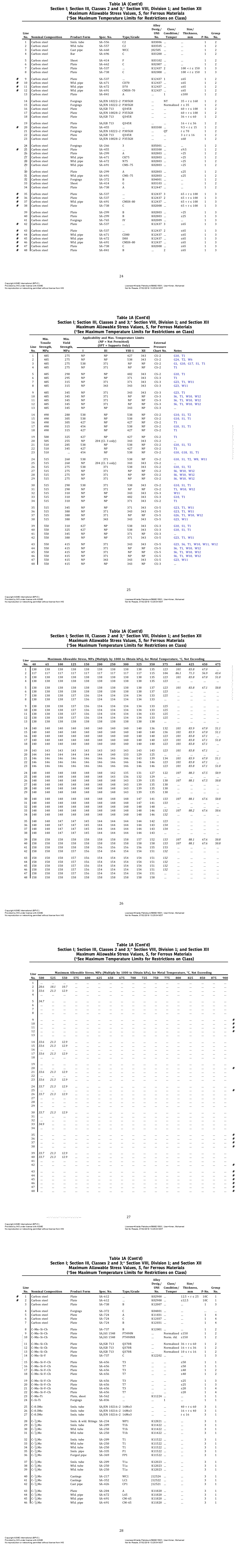

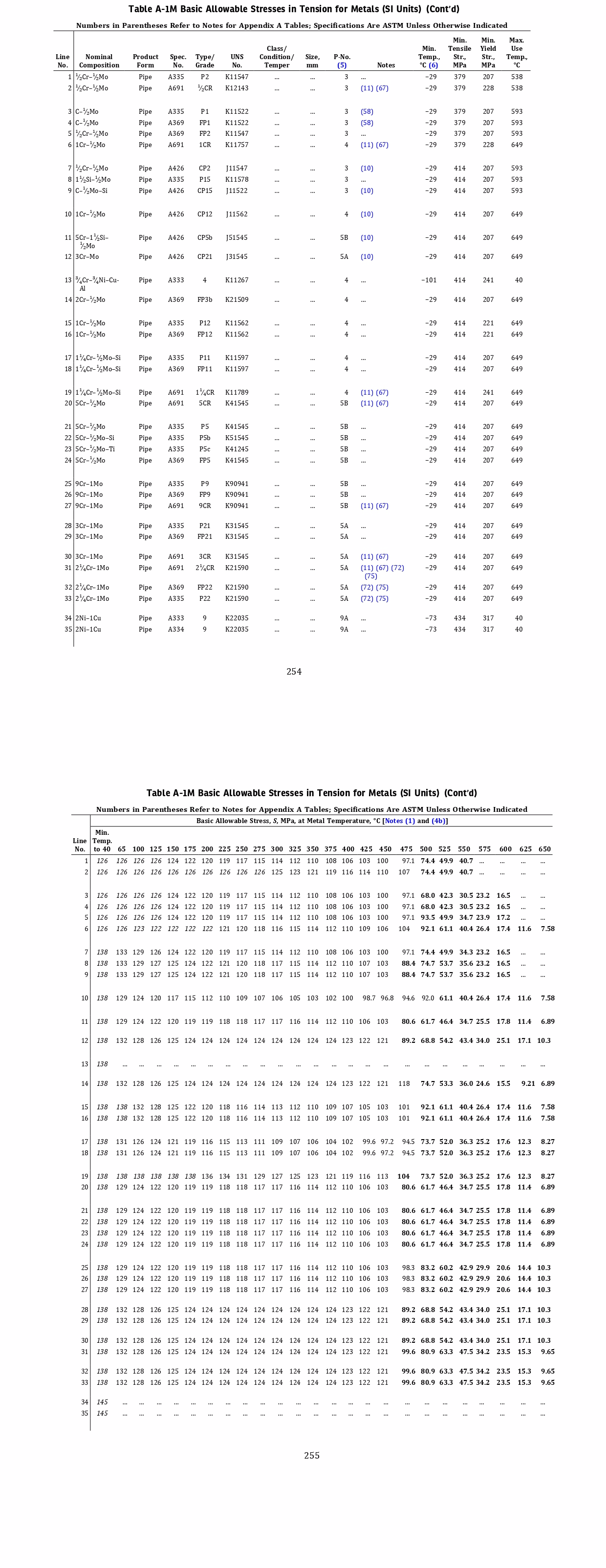

- Maximum Allowable Stress Section ii part D تنش مجاز متریال A106 Grade B در دمای ۴۳۵ درجه سانتیگراد

- Thickness Calculation of blind flange مثال هایی برای محاسبه ضخامت ورق برای ساخت فلنج کور بر اساس UG-34

- Bolt root and tensile stress area

- Pressure-Temperature rating B16.5

- Yield Strength for material A105 section ii part D استحکام تسلیم فلنج A105 جدول Y-1 سکشن ii در دماهای مختلف

- Required Wall thickness حداقل ضخامت مورد نیاز براساس بند ug-34 و فرمول یک اپندیکس 2 ( سرهای مسطح دایره ای )

- ( Required Wall Thickness ( Mininmum مثال از حداقل ضخامت Blind flange سایز ۳۴ اینچ

- Flange rating Maximum Design Pressure - حداکثر فشار طراحی بر اساس Asme B16.5

- دختران ایرانی زیر پای سگ های ارتش آمریکا توضیحاتی درباره وضعیت برخی دختران در زمان شاه

- Maximum Stress value SA-312 TP316L حداکثر تنش مجاز متریال در دماهای مختلف

- Asme PCC-1 appendix H-O bolt stress - bolt root area

- Root area + Tensile stress area Bolt

- Bolt root + tensile area ASME B1-1 for threads

- داستان سید مهدی قوام و زن ...

- شارلی ابدو فرانسه

- تجاوز وحشیانه چند افغان به یک زن جوان در فرحزاد

- ورزش با حرکات موزون + موسیقی

- دامی ساپورت انواع مختلف نصب

- اپلیکیشن دامی ، مایتر زانویی و شلوارک

- YJC.IR

- عیوب جوش

ابر برچسب

Dummy support Branch دامی ساپورت Unequal Branch Miter Pipe Branch PWHT Dummy پایپینگ Miter bend piping ELBOW DEGREE مخروط ناقص impact test مهسا امینی ردیوسر Pipe To Cone شابلون دامی ساپورت Y Piece شابلون برنچجدیدترین یادداشتها

همه- Sizing 6dB or 20dB Drop زمانیکه اندازه ناپیوستگی بزرگتر از قطر ترانسدیوسر باشد،طول ناپیوستگی قانون ۶ دسی بل قابل اندازه گیری است. اسکن می کنیم...

- بازرسی جوش به روش UT و حد پذیرش یک استاد دانشگاه درباره اقدام اخیر متروی تهران نوشت: برگزاری مسابقه نامه خودمونی به خدا از سوی مترو کار خوبی است اما...

- Piping isometric elbow degree calculation یک استاد دانشگاه درباره اقدام اخیر متروی تهران نوشت: برگزاری مسابقه نامه خودمونی به خدا از سوی مترو کار خوبی است اما...

- سوالات تست مایعات نافذ ASNT Developer types Dry powder method of application : Dust/fog, dip Application sequence : After drying Dwell time : 1/2...

- multiple PQRs used to support a single WPS, مدیران اماکن عمومی و صاحبان و متصرفان اماکن خصوصی موظفاند توقف اتباع خارجی را ظرف مدت 24 ساعت پس از ورود آنان، به مرجع...

- Thickness Of Base Metal Qualified پدر دانشآموزان جانباخته خطاب به وزیر آموزش و پرورش: نه تسلیت میخواهم watch ‹ www.youtube.com ۲۱ بهمن ۱۴۰۳ · پدر...

- TEST COUPON IN PIPE AND MIN LENGTH مدیران اماکن عمومی و صاحبان و متصرفان اماکن خصوصی موظفاند توقف اتباع خارجی را ظرف مدت 24 ساعت پس از ورود آنان، به مرجع...

- هدف از صلاحیت جوشکار هدف از احراز صلاحیت فردی که از فرآیند اتصال استفاده می کند، نشان دادن توانایی آن فرد برای تولید یک اتصال سالم و بی عیب...

- VALVE DBB ( double block and bleed ) شیر انسداد و تخلیه ... با دو سطح نشیمن که در حالت بسته، در برابر فشار از دو سر شیر با...

- Visual Testing Quiz تقریظ واژهای عربی مأخوذ از «قَرَظَ»، در لغت به معنای مدح و ستایش است. قَرِظَ قرظاً؛ مهترو ارجمند گردید بعدِ مذلت و...

- PT QUIZ -کندن کانال چندروز طول کشید؟ در مجموع ۵۵ روز کانال کندیم و در ۹ روز آخر فقط من و حسن رعیت بودیم که خوشبختانه توانستیم...

- Wire IQI حکم اعدام ظریف در دادگاه صحرایی چه معنایی دارد؟ - فرارو سیاست ‹ سیاست ‹ fararu.com ۱۳ بهمن ۱۴۰۳ ... ظریف برکنار و...

- PIPING-NDT پسر قاضی مقیسه در صفحه شخصی خود در فضای مجازی نوشت: حاجی دو بار برای عمل جراحی نیروی خدماتی (قاتل منافق) از همه قضات...

- انجام تست جوش با روش مایعات نافذ بهمن ماه ۱۴۰۳ پسر قاضی مقیسه در صفحه شخصی خود در فضای مجازی نوشت: حاجی دو بار برای عمل جراحی نیروی خدماتی (قاتل منافق)...

- Cone ترک ها ضرب المثلی دارند که : balık baştan kokar یعنی ماهی از سر گندیده میشود. منظور این است که آب از سرچشمه گل آلود...

- فشار تست در High Pressure piping فصل IX سلام بر او؛ روزى که زاده شد و روزى که مىمیرد و روزى که دیگر بار زنده برانگیخته مىشود. ( حضرت عیسی ) for the signs of...

- Severe cyclic condition Severe cyclic is not a fluid service 305.2.3 Pipe for Severe Cyclic Conditions (a) Except as limited in (b) through (d)...

- درصد رادیوگرافی طبق Asm3 B31.3 حکم اعدام ظریف در دادگاه صحرایی چه معنایی دارد؟ - فرارو سیاست ‹ سیاست ‹ fararu.com ۱۳ بهمن ۱۴۰۳ ... ظریف برکنار و...

- TESTING کپسول تامیفلو (تامی فلو) 45 میلی گرم | TAMIFLU Capsule 45 mg TAMIFLU-Capsule-4... ‹ www.darooyab.ir موارد مصرف کپسول...

- Y Ducting Connector ventilation اسلتامیویر دارو اُسِلتامیویر با نام تجاری تامیفلو یک داروی آنتیویروس است که فعالیت ویروس آنفلوآنزا را در بدن مسدود...

- Lateral Pipe Branch 12 × 4 thk 5.49 سرانجام بشار اسد در ۱۸ آذر ۱۴۰۳ سرنگون گردید زندان صیدنایا - ویکیپدیا، دانشنامهٔ آزاد زندان_صیدنایا ‹ wiki ‹...

- Elbow Side Joint ویدیویی از یک مدیر در کارخانهای در فضای مجازی منتشر شده که سراغ کارگرانش میرود و به آنها بابت نزدن ریششان هشدار...

- زاویه بین سوراخ های فلنج 360 ÷ Number Of Holes چهلم ( ۱۰ آبانماه ۱۴۰۳ ) مجاهدان عرصه اقتصاد کشور روحشان شاد و یادشان گرامی فوت ( ۵۳ نفر ) : بعلت...

- CON PIPE REDUCER امیر نصیرزاده در پاسخ به سوالی درباره آسیب دیدن یک مرکز در شاهرود و احتمال حمله از مرزهای شمالی عنوان کرد: خیر چنین...

- ماکزیمم فشار داخلی مجاز برای لوله ها در مخازن تحت فشار MAWP امیر نصیرزاده در پاسخ به سوالی درباره آسیب دیدن یک مرکز در شاهرود و احتمال حمله از مرزهای شمالی عنوان کرد: خیر چنین...

- CLOD BEND طبق استاندارد ملی گاز ایران ماکزیمم زاویه خم بر اساس ۱۲ متر لوله داده شده مثلاً برای سایز ۴ اینچ حداکثر 118 درجه ... در...

- رسم فنی انشعاب y piece

- Duct Pattern ..... مایترکاری ۲۹ مهر ۱۴۰۲ ۱۹ روز پس از عملیات موشکی ایران علیه اسرائیل، خبرگزاری فارس از قول یک منبع آگاه نوشت که در این عملیات (...

- نیاز به تست ضربه و معافیت ها در Asme سکشن 8 بخش یک بازداشت بعلت اقدام علیه امنیت ملی ASME VIII DIV 1 2017 UG-20(f) →→→UCS-66(a) →→→ UCS-66(b) →→→UCS-68(c) در وهله اول به...

- زمان holding تنش زدایی کربن استیل در Asme سکشن 8 در کد مخزن تحت فشار Div 1 جنس کربن استیل با ضخامت 32 میل و بیشتر به تنش زدایی نیاز دارند منتهی یک معافیت با توجه به...

بایگانی

- اردیبهشت 1404 3

- فروردین 1404 1

- بهمن 1403 8

- دی 1403 5

- آذر 1403 3

- آبان 1403 8

- مهر 1403 15

- شهریور 1403 28

- مرداد 1403 3

- تیر 1403 2

- خرداد 1403 12

- اردیبهشت 1403 20

- فروردین 1403 2

- اسفند 1402 3

- بهمن 1402 11

- دی 1402 24

- آذر 1402 55

- آبان 1402 17

- مهر 1402 1

- شهریور 1402 3

- مرداد 1402 1

- خرداد 1402 3

- اردیبهشت 1402 3

- فروردین 1402 4

- اسفند 1401 10

- بهمن 1401 15

- آذر 1401 8

- آبان 1401 25

- مهر 1401 7

- شهریور 1401 13

- مرداد 1401 6

- تیر 1401 2

- خرداد 1401 13

- اردیبهشت 1401 1

- دی 1400 2

- آذر 1400 15

- آبان 1400 44

- شهریور 1400 6

- مرداد 1400 27

- تیر 1400 38

- خرداد 1400 16

- اردیبهشت 1400 4

- فروردین 1400 10

- اسفند 1399 8

- بهمن 1399 6

- دی 1399 3

- آذر 1399 2

- شهریور 1399 9

- فروردین 1399 10

- بهمن 1398 12

- آذر 1398 8

- آبان 1398 5

جستجو

لوله های فولاد آلیاژی A691

EFW

16" and Over

CM-65 carbon-molybdenum steel

CM-70 carbon-molybdenum steel

CM-75 carbon-molybdenum steel

CMSH-70 carbon-manganese-silicon steel, normalized

CMS-75 carbon-manganese-silicon steel

CMSH-80 carbon-manganese-silicon steel, quenched and tempered

2 1⁄2 CR 1⁄2 % chromium, 1⁄2 % molybdenum steel

1CR 1 % chromium, 1⁄2 % molybdenum steel

11⁄4 CR 11⁄4 % chromium, 1⁄2 % molybdenum steel

21⁄4 CR 21⁄4 % chromium, 1 % molybdenum steel

3CR 3 % chromium, 1 % molybdenum steel

5CR 5 % chromium, 1⁄2 % molybdenum steel

9CR 9 % chromium, 1 % molybdenum steel 2

9 % chromium, 1 % molybdenum, vanadium, niobiumC

| Pipe Grade | ASTM Specification | Post-Weld Heat-Treat Temperature Range (Stress Relieving), °F (°C) | Normalizing Temperature max unless otherwise noted, | Quenching Temperature max unless otherwise noted,°F (°C) | Tempering Temperature, min, °F (°C) |

| CM-65 | A 204/A 204M | 1100 to 1200 (590 to 650) | 1700 (925) | … | … |

| CM-70 | A 204/A 204M | 1100 to 1200 (590 to 650) | 1700 (925) | … | … |

| CM-75 | A 204/A 204M | 1100 to 1200 (590 to 650) | 1700 (925) | … | … |

| CMSH-70 | A 537/A 537M | 1100 to 1200 (590 to 650) | 1700 (925) | … | … |

| CMS-75 | A 299/A 299M | 1100 to 1200 (590 to 650) | 1700 (925) | … | … |

| CMSH-80 | A 537/A 537M | 1100 to 1200 (590 to 650) | A | 1700( 925) | 1100 to 1250 (590 to 675) |

| 1/2CR | A 387/A 387M | 1100 to 1300 (590 to 705) | 1850 (1010) | 1700( 925) | 150 to 1375 (620to745) |

| 1CR | A 387/A 387M | 1100 to 1350 (590 to 730) | 1850 (1010) | 1700 (925) | 150 to 1375 (620to745) |

| 11⁄4CR | A 387/A 387M | 1100 to 1375 (590 to 745) | 1850 (1010) | 1700 (925) | 150 to 1375 (620to745) |

| 21⁄4CR | A 387/A 387M | 1200 to 1400 (650 to 760) | 1850 (1010) | 1700 (925) | 250 to 1400(675 to760) |

| 3CR | A 387/A 387M | 1200 to 1400 (650 to 760) | 1850 (1010) | 1700 (925) | 250 to1400 (675 to760) |

| 5CR | A 387/A 387M | 1200 to 1400 (650 to 760) | 1850 (1010) | 1650 (900) | 1300 to1400 (705 to760) |

| 9CR | A 387/A 387M | 1325 to 1375 (715 to 745) | B | … | 1325 to1375 (715 to745) |

| 91 | A 387/A 387M | 1350 to 1420 (730 to 770) | 11900 to 2000 (1040 to 1095) | 1900 min (1040 min) | 1350 to 1440 (730 to 780) |

In the 1999 Addenda to the 1998 Edition, ASME changed the factor of safety from 4 times to 3.5 times, increasing the allowable stress values.

factor Of Safety 3 in Asme B31.3

در تصویر زیر حداقل استحکام کششی برای متریال A691 در جدول ( A-1M ( Metric داده شده ، با توجه به Grade و ملاحظه ستون ترکیب شیمیایی متفاوت است

302.3.2 Bases for Design Stresses.

d) Other Materials. Basic allowable stress values at temperature for materials other than bolting materials, cast iron, and malleable iron shall not exceed the lowest of the following:

(1) the lower of one-third of ST and one-third of tensile strength at temperature

(2) except as provided in (3) below, the lower of two-thirds of SY and two-thirds of yield strength at temperature

(3) for austenitic stainless steels and nickel alloys having similar stress–strain behavior, the lower of two- thirds of SY and 90% of yield strength at temperature [see (e) below]

(e) Application Limits. Application of stress values determined in accordance with para. 302.3.2(d)(3) is not recommended for flanged joints and other components in which slight deformation can cause leakage or mal- function. [These values are shown in italics or boldface in Table A-1, as explained in Note (4) to Appendix A Tables.] Instead, either 75% of the stress value in Table A-1 or two-thirds of the yield strength at temperature listed in the BPV Code, Section II, Part D, Table Y-1 should be used